Maximizing Efficiency in Drone Motor Winding Machines and Production Lines

In the rapidly advancing field of drone technology, the quality and performance of drone motors are vital to the overall success of the product. To enhance these motors, drone motor winding machines and production lines play a crucial role in ensuring consistent quality and high production rates. However, many manufacturers face the challenge of balancing speed with scrap reduction. By optimizing the processes within these machines and production lines, manufacturers can not only increase their throughput but also significantly reduce waste. Let’s explore seven proven methods to boost speed and cut scrap when working with drone motor winding machines and production lines.

Optimize Your Production Line Layout for Maximum Efficiency

Streamlining Workstations for Faster Throughput

To enhance efficiency, consider positioning workstations in a manner that minimizes the movement of materials and workers. Each station should flow logically from one to the next to avoid bottlenecks. This reduces the time spent handling and reorienting components, enabling faster production times without compromising quality.

Incorporating Automated Systems

Automation has revolutionized manufacturing processes across industries, and drone motor winding is no exception. Automated systems can handle repetitive tasks more efficiently than manual labor, such as wire feeding or component inspection, thus reducing the risk of human error and speeding up the production line. Implementing robotics can also improve consistency, leading to fewer defects and reduced scrap.

Invest in High-Quality Materials to Reduce Waste

Using Premium Wires and Components

Investing in premium copper wires and other motor components may initially appear expensive, but the enhanced conductivity and reliability result in a better-performing motor. Premium wires are more durable and less prone to damage during winding, which reduces the likelihood of defects and scrap during production.

Quality Control from the Start

Incorporating a robust quality control process at the raw materials stage can catch potential issues before they escalate during production. This proactive approach helps minimize scrap caused by poor-quality materials entering the production line.

Precision Winding Techniques to Improve Accuracy

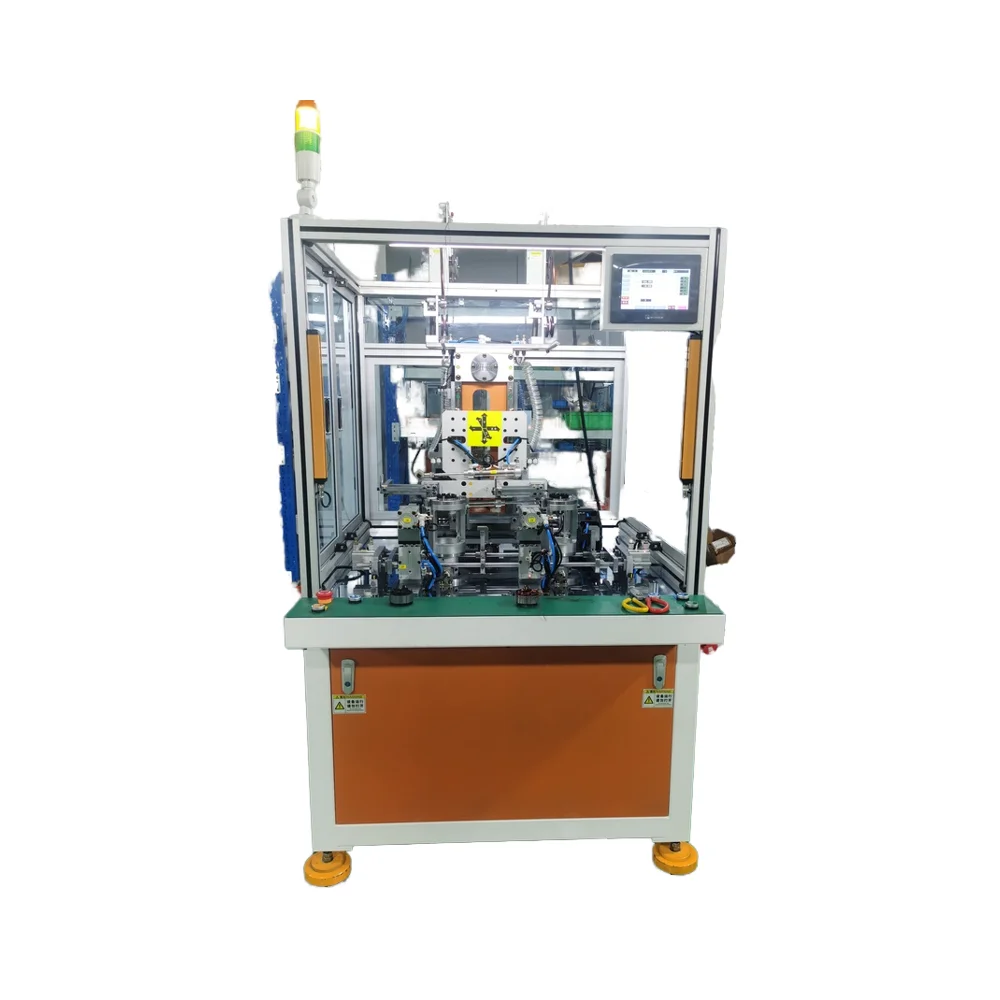

Advanced Winding Machines

Modern drone motor winding machines equipped with precision control systems can ensure that the wire is wound with exact accuracy. These machines can also adjust for slight variations in wire tension, diameter, and angle, which significantly reduces the chances of errors that can lead to scrap.

Computerized Control Systems

Computerized control systems allow manufacturers to set specific parameters and monitor each step of the winding process. This technology ensures consistent quality and can be adjusted quickly to suit different motor designs or requirements, reducing the likelihood of defects.

Optimize Machine Settings for Speed and Accuracy

Regular Calibration and Maintenance

Performing regular machine calibration ensures that winding machines operate within optimal parameters, reducing the likelihood of inconsistent winding that leads to scrap. In addition, regular maintenance helps avoid unexpected breakdowns, which can result in production delays and wasted materials.

Using Real-Time Monitoring Systems

Real-time monitoring systems track the performance of machines and can alert operators to any irregularities before they become significant issues. By utilizing sensors and data analytics, manufacturers can identify areas where speed can be increased without compromising quality.

Train and Empower Operators for Better Results

Continuous Operator Training

Offering continuous training to operators ensures they are familiar with the latest techniques, machine settings, and troubleshooting processes. This knowledge empowers them to handle challenges quickly and effectively, preventing production delays that could result in scrap.

Creating a Culture of Quality Control

Empowering operators to take ownership of quality control can greatly benefit the overall production process. If they are trained to identify defects early on and address them before they escalate, scrap can be significantly reduced.

Implement Lean Manufacturing Principles

Identifying and Eliminating Bottlenecks

Lean manufacturing focuses on identifying bottlenecks in the production process and eliminating them. By using value stream mapping techniques, manufacturers can visually represent their workflow, identify delays, and optimize the line for better speed and lower scrap.

Continuous Improvement Culture

Establishing a culture of continuous improvement (kaizen) within the production line encourages employees at all levels to suggest improvements. This collaborative approach can uncover hidden inefficiencies and lead to innovative solutions that boost speed while cutting down on scrap.

Perform Regular Audits and Data Analysis for Long-Term Success

Statistical Process Control (SPC)

Statistical process control involves using data analytics to monitor and control the production process. By measuring key metrics such as winding tension, coil resistance, and motor output, manufacturers can identify trends that may indicate potential quality issues. Early detection allows for corrective actions to be taken before large quantities of scrap are produced.

Root Cause Analysis

When scrap rates do spike, it’s essential to perform a root cause analysis. By thoroughly investigating the reasons behind the increase in defects, manufacturers can take targeted actions to address the problem at its source, improving both efficiency and quality in the long run.

FAQ

How can I improve the speed of my drone motor winding machines without increasing scrap?

Optimizing your production line layout, investing in automation, regularly maintaining your machines, and training your operators are key strategies to increase speed without sacrificing quality.

What are the best materials for reducing scrap in drone motor production?

Premium copper wires and high-quality motor components are less likely to cause defects during the production process, helping reduce overall scrap and improve motor performance.

How often should I calibrate my drone motor winding machines?

Regular calibration—ideally, every few months or after every major production run—is essential to ensure the machines are operating within optimal parameters, reducing the risk of errors and scrap.

What role does lean manufacturing play in reducing scrap?

By identifying and eliminating inefficiencies, lean manufacturing helps reduce waste across the production line, improving both speed and quality. Continuous improvement strategies also contribute to long-term reductions in scrap.

Table of Contents

- Maximizing Efficiency in Drone Motor Winding Machines and Production Lines

- Optimize Your Production Line Layout for Maximum Efficiency

- Invest in High-Quality Materials to Reduce Waste

- Precision Winding Techniques to Improve Accuracy

- Optimize Machine Settings for Speed and Accuracy

- Train and Empower Operators for Better Results

- Implement Lean Manufacturing Principles

- Perform Regular Audits and Data Analysis for Long-Term Success

- FAQ