Choosing the Right Drone Motor Winding Machines and Production Lines for 6-Inch Racing Drones

The world of drone racing is highly competitive, with manufacturers striving to design faster, more efficient, and durable drones. Among the critical components of these high-performance drones are the motors, which drive the speed and agility needed in racing scenarios. For 6-inch racing drones, selecting the right motor winding machines and production lines is crucial. These machines play a vital role in ensuring high precision, speed, and consistency in motor production. In this article, we will explore how to select the ideal drone motor winding machines and production lines tailored to the unique demands of 6-inch racing drones.

Understanding the Importance of Motor Quality for 6-Inch Racing Drones

Performance Demands of 6-Inch Racing Drones

Racing drones are designed to achieve maximum speed and maneuverability, often requiring motors that can handle high RPMs (revolutions per minute) and provide strong thrust without compromising on weight. 6-inch racing drones, in particular, rely on lightweight yet powerful motors that can deliver quick acceleration and smooth handling during tight turns and high-speed maneuvers. The motor must also maintain stability and control during sharp movements and sudden changes in direction.

Role of Motor Winding Machines in Ensuring Motor Quality

The winding process plays a crucial role in determining the efficiency and performance of a drone motor. A high-quality motor winding machine ensures that the coils are wound with the utmost precision, resulting in better conductivity and overall motor performance. This directly influences the drone's thrust, battery life, and heat management, which are critical factors in racing. A high-efficiency motor is crucial to extending flight times and providing competitive performance in races.

Key Factors to Consider When Choosing Drone Motor Winding Machines

Precision and Accuracy in Winding

The precision of the winding process is essential for ensuring the motor coils are evenly wound and the wire tension is consistent. Variations in the winding process can lead to uneven coils, causing inefficiencies that directly impact the motor's performance. A high-precision winding machine is necessary to meet the tight tolerances required for 6-inch racing drones. Even slight inaccuracies can result in imbalance, inefficiency, or increased wear on the motor, all of which are detrimental in a racing environment.

Speed and Throughput

Racing drones require motors to be produced at high speeds without compromising quality. A fast, reliable winding machine can ensure that the production process keeps pace with the demand for motors, allowing manufacturers to meet tight deadlines. It is essential to strike a balance between speed and quality to avoid high scrap rates. Fast production times ensure that motors are readily available for assembly, but speed should not come at the cost of motor accuracy or performance.

Choosing the Right Production Line for Drone Motor Manufacturing

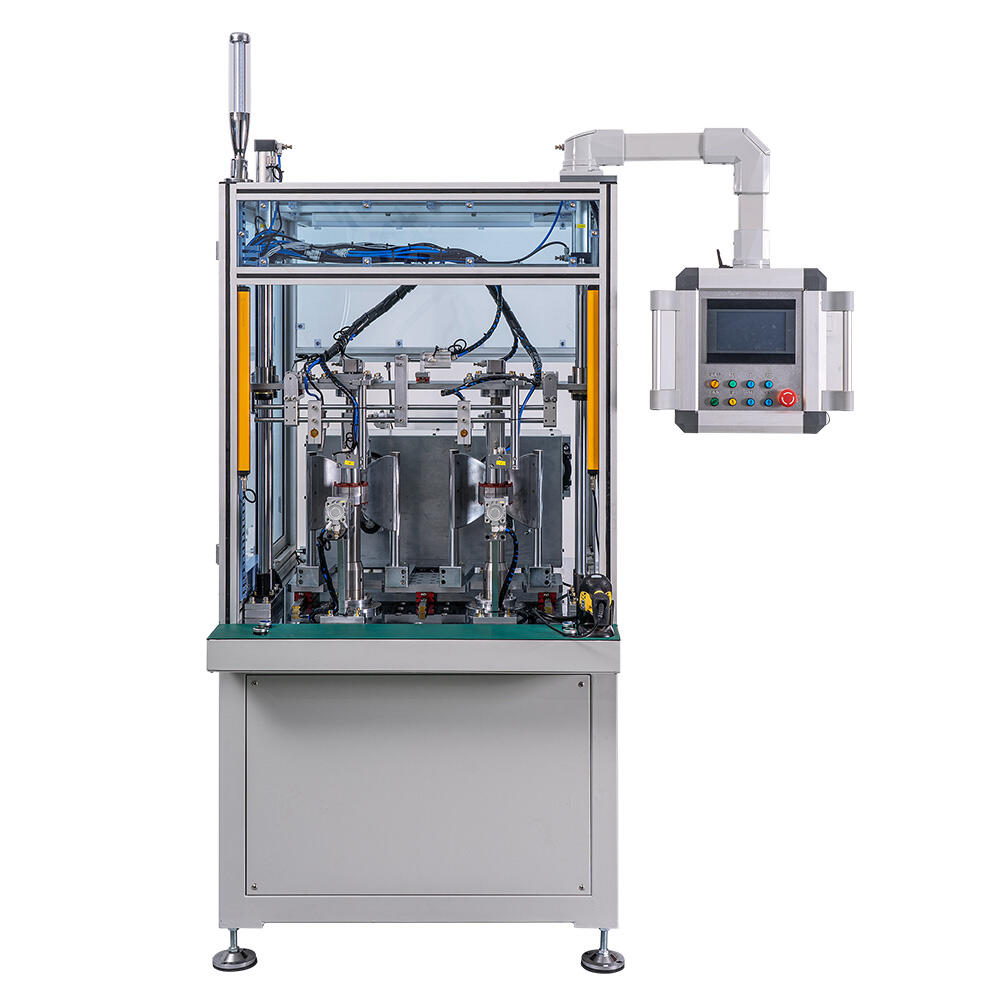

Integration of Automation in the Production Line

Automated production lines can help streamline the manufacturing process, reducing human error and speeding up production times. Automation in tasks such as wire feeding, coil shaping, and motor testing can significantly reduce the risk of defects while improving the overall speed of motor production. Automation systems can also allow for real-time monitoring, providing immediate feedback on motor quality and potential issues.

Quality Control and Testing

Quality control is an essential aspect of any production line, particularly in the high-performance environment of drone racing. The production line should incorporate rigorous testing systems to verify that each motor meets the required specifications. From resistance testing to thermal management checks, having integrated testing stations ensures that motors are fit for high-stakes racing environments. These tests should be done at every step of production to catch any potential issues early, reducing scrap and minimizing the chance of a faulty motor being released for use in drones.

Machine Calibration and Maintenance for Consistency

Regular Calibration Procedures

Regular calibration of the winding machines ensures that every motor is produced according to precise specifications. Calibration helps in adjusting for any minor machine wear or material variances that could affect the winding process. A well-calibrated machine ensures that each motor coil is wound to the exact requirements for optimal efficiency and performance. Without proper calibration, the motor's performance could degrade, resulting in overheating, reduced thrust, and potential failure during racing.

Scheduled Maintenance for Optimal Performance

Routine maintenance checks are essential for keeping the production line running smoothly. These checks should include inspecting mechanical parts, cleaning components, and updating software controls. A well-maintained machine performs more reliably and reduces the likelihood of unexpected downtime. Regular maintenance also extends the lifespan of the equipment, which is critical in a competitive industry where production uptime is crucial. Furthermore, proactive maintenance prevents issues from becoming significant disruptions in the production process.

Automation vs. Manual Processes in Motor Production

Advantages of Automation in Motor Production

Automation is essential for meeting high-volume production demands. It speeds up the winding process, reduces human error, and ensures that every motor is produced consistently. Automated systems also make it easier to scale production up or down based on market demand without sacrificing quality. Additionally, automated systems can be programmed for different types of motors, making it easier to adjust production based on specific design changes or customer requirements.

When Manual Processes Still Make Sense

While automation is ideal for large-scale production, some aspects of motor manufacturing may still benefit from manual intervention. For instance, fine-tuning coil winding or making adjustments to specific motor designs may require manual oversight to ensure optimal performance in specialized applications like racing drones. Manual processes may also allow for more flexibility in addressing specific design requests that may not be easily handled by automated systems.

Customizing Your Production Line for 6-Inch Racing Drones

Adapting Machines for High-Speed Motors

6-inch racing drones demand motors that can handle extreme speeds and rapid acceleration. The production line must be customized to produce motors with high efficiency, superior cooling, and low weight. Specialized machines may be necessary to accommodate the lightweight but powerful motors needed for racing. These motors must also be capable of sustaining high thrust without experiencing thermal overload or mechanical failure.

Tailoring Testing Stations for Racing Standards

Testing stations along the production line should be tailored to meet the rigorous standards required for racing drones. This includes testing for motor torque, power efficiency, and durability under high-stress conditions. Customizing the testing process ensures that each motor is ready for high-speed, high-performance environments. This includes checking for resistance and heat tolerance, as well as testing under simulated racing conditions to ensure the motor can withstand the extreme demands placed on it during a race.

FAQ

How do I know if my motor winding machine is producing accurate coils?

To ensure the accuracy of your coils, check the machine's precision and the consistency of the winding process. Regular calibration and quality control checks can verify the accuracy of each coil produced. Monitoring the performance of each motor after production also helps identify any inconsistencies early.

What is the most important factor in selecting a production line for 6-inch racing drones?

The most important factor is ensuring that the production line can handle the high precision, speed, and testing required for racing drone motors. Automation, quality control, and customization are key considerations. The production line should be adaptable to the high-speed demands and precise tolerances needed for racing.

Can I rely on manual processes for producing motors for racing drones?

While manual processes can offer flexibility, automation is generally recommended for high-volume production of racing drone motors. It ensures consistency, speed, and precision that manual processes may not achieve at scale. However, manual processes may still be beneficial for specific, custom motor designs or minor adjustments.

How often should I calibrate my motor winding machine?

Calibration should be done regularly, typically every few months or after significant production runs, to ensure that machines continue to produce motors to the required specifications. This helps maintain consistency in the winding process, minimizing errors and defects.

Table of Contents

- Choosing the Right Drone Motor Winding Machines and Production Lines for 6-Inch Racing Drones

- Understanding the Importance of Motor Quality for 6-Inch Racing Drones

- Key Factors to Consider When Choosing Drone Motor Winding Machines

- Choosing the Right Production Line for Drone Motor Manufacturing

- Machine Calibration and Maintenance for Consistency

- Automation vs. Manual Processes in Motor Production

- Customizing Your Production Line for 6-Inch Racing Drones

- FAQ