Proper maintenance of DC motor components is essential for optimal performance and longevity. The commutator, which works in close conjunction with the motor shaft, requires systematic care to prevent premature wear and ensure reliable operation. Understanding the relationship between these critical components and implementing effective maintenance strategies can significantly extend your motor's operational life while reducing costly downtime and repairs.

Understanding Commutator Function and Motor Shaft Integration

The Critical Connection Between Commutators and Motor Shafts

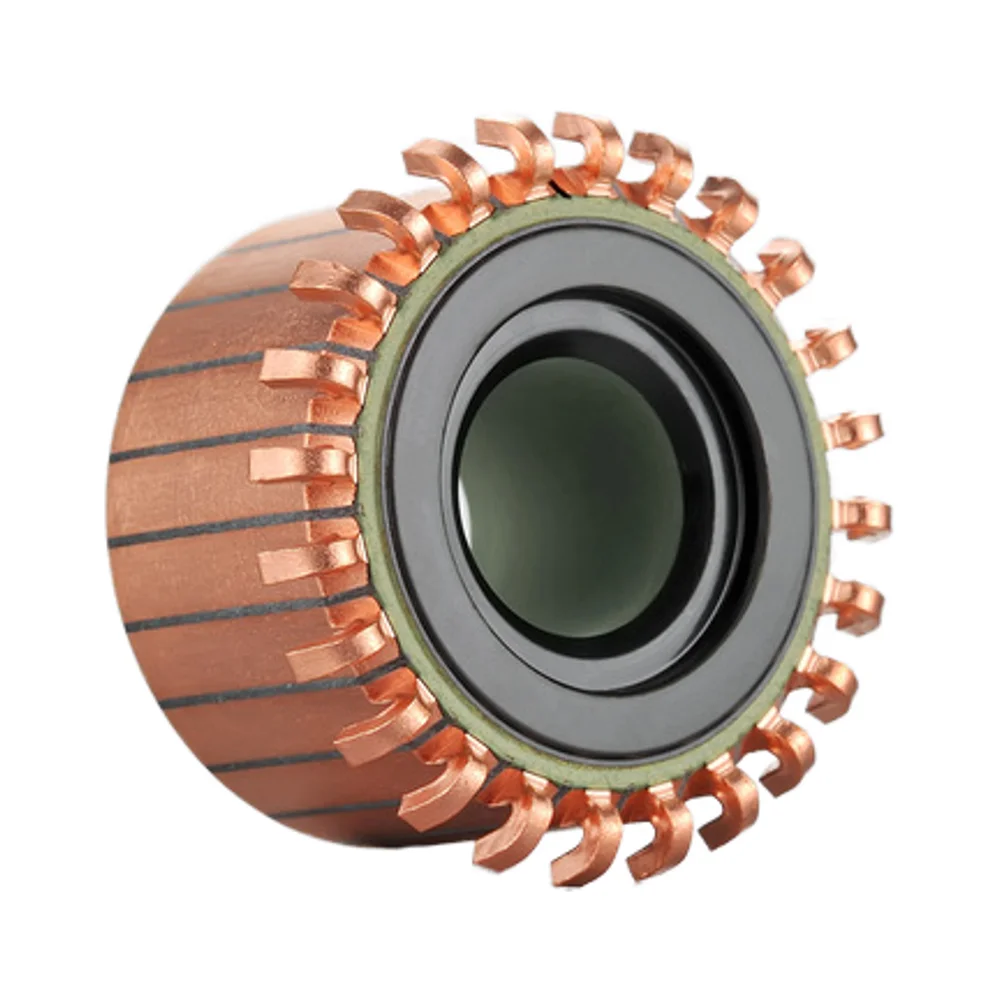

The commutator serves as the mechanical rectifier in DC motors, converting the alternating current induced in the rotor windings into direct current in the external circuit. This component is precisely mounted on the motor shaft and rotates as a single unit, making their alignment and condition interdependent. When the motor shaft experiences wear or misalignment, it directly affects commutator performance, leading to increased sparking, uneven brush contact, and reduced efficiency.

The segmented design of the commutator requires perfect concentricity with the motor shaft to maintain proper electrical contact with the carbon brushes. Even minor deviations in shaft straightness or bearing wear can cause the commutator segments to move out of their optimal position, resulting in poor electrical continuity and accelerated component degradation.

Common Issues Affecting Commutator-Motor Shaft Assembly

Several factors can compromise the integrity of the commutator and motor shaft assembly. Thermal expansion and contraction cycles can cause loosening of the commutator's connection to the shaft, particularly in applications with frequent start-stop operations. Contamination from carbon dust, oil, or environmental debris can accumulate between commutator segments, creating electrical shorts and uneven current distribution.

Mechanical vibration and shock loads transmitted through the motor shaft can cause gradual loosening of commutator segments or damage to the insulation between segments. This mechanical stress is particularly problematic in industrial applications where motors operate under variable load conditions or in harsh environments with significant mechanical disturbances.

Essential Maintenance Practices for Optimal Performance

Regular Inspection and Cleaning Protocols

Establishing a systematic inspection schedule forms the foundation of effective commutator maintenance. Visual examination should focus on the commutator surface for signs of excessive wear, burning, or segment separation. The motor shaft alignment and bearing condition should be assessed simultaneously, as these factors directly impact commutator performance.

Cleaning procedures must remove carbon dust and debris without damaging the delicate commutator segments. Using compressed air at appropriate pressure levels helps dislodge loose particles, while specialized cleaning solvents can remove stubborn deposits. The cleaning process should extend to the motor shaft area, ensuring that no contamination affects the mechanical connection between components.

Proper Tool Selection and Maintenance Techniques

Commutator maintenance requires specific tools designed to preserve the precise geometry of the segments while removing wear and contamination. Commutator stones or specialized abrasive materials should match the hardness characteristics of the commutator material to avoid excessive removal or surface damage. The selection of appropriate tools becomes critical when working with high-performance motors where tolerances are particularly tight.

Undercutting tools maintain proper insulation between commutator segments by removing material from the mica or plastic separators. This process ensures that segment-to-segment electrical isolation remains intact while allowing for proper brush contact across the commutator surface. The depth and consistency of undercutting directly affects both electrical performance and mechanical stability of the entire assembly.

Advanced Troubleshooting and Diagnostic Methods

Electrical Testing and Performance Analysis

Comprehensive electrical testing provides valuable insights into commutator condition and its interaction with the motor shaft assembly. Resistance measurements between adjacent segments should show consistent values, with significant deviations indicating potential insulation breakdown or segment damage. These measurements help identify problems before they result in catastrophic failure or extensive damage to surrounding components.

Voltage drop testing across the commutator surface while the motor operates under load reveals uneven contact resistance and brush positioning issues. This dynamic testing approach captures performance variations that static measurements might miss, particularly those related to motor shaft runout or bearing irregularities that only manifest during rotation.

Mechanical Assessment and Alignment Verification

Precise mechanical measurements ensure that the commutator maintains proper alignment with the motor shaft throughout its operational life. Runout measurements using dial indicators can detect shaft bending or bearing wear that affects commutator concentricity. These mechanical assessments should be performed at regular intervals, particularly in applications with high mechanical stress or frequent thermal cycling.

Torque verification of commutator mounting hardware prevents loosening that could lead to catastrophic failure. The connection between the commutator and motor shaft must maintain its integrity under all operating conditions, requiring proper initial installation and periodic verification of joint tightness. Documentation of these measurements creates a baseline for trending analysis and predictive maintenance scheduling.

Preventive Maintenance Scheduling and Best Practices

Developing Effective Maintenance Intervals

Maintenance frequency depends on operating conditions, duty cycle, and environmental factors affecting both the commutator and motor shaft. High-duty applications require more frequent inspection and maintenance, while motors in clean, stable environments may operate longer between service intervals. The key lies in establishing data-driven schedules based on actual wear patterns and performance degradation trends.

Condition-based maintenance strategies utilize vibration monitoring, temperature measurement, and electrical parameter trending to optimize maintenance timing. This approach prevents both premature maintenance activities and unexpected failures by responding to actual component condition rather than arbitrary time intervals. The integration of multiple monitoring methods provides comprehensive insight into overall motor health.

Documentation and Record Keeping

Systematic record keeping enables trending analysis and helps identify patterns in component wear and failure modes. Maintenance records should include detailed measurements, observations, and photographs documenting commutator condition and motor shaft alignment over time. This documentation proves invaluable for warranty claims, failure analysis, and optimizing future maintenance strategies.

Digital maintenance management systems facilitate data storage, analysis, and reporting while enabling predictive maintenance algorithms. These systems can correlate maintenance activities with performance metrics, helping identify the most effective maintenance practices and optimal component replacement timing.

Safety Considerations and Professional Standards

Electrical Safety During Maintenance

All electrical maintenance work requires proper lockout/tagout procedures to ensure complete de-energization before beginning work. The motor shaft and commutator assembly retain electrical charge even after power disconnection, requiring specific discharge procedures to ensure worker safety. Proper personal protective equipment includes insulated tools, safety glasses, and appropriate clothing to prevent injury from electrical or mechanical hazards.

Testing equipment must be properly calibrated and rated for the voltage levels present in the motor system. Improper test equipment can create safety hazards and provide inaccurate readings that lead to incorrect maintenance decisions. Regular calibration verification ensures both safety and measurement accuracy throughout the maintenance process.

Environmental and Contamination Control

Maintenance activities should be performed in clean environments to prevent contamination of the commutator and motor shaft surfaces. Carbon dust generated during commutator maintenance requires proper containment and disposal to prevent environmental contamination and health hazards. Appropriate ventilation systems remove airborne particles while maintaining safe working conditions.

Chemical cleaning agents used in maintenance procedures must be selected for compatibility with motor materials and environmental regulations. Proper disposal of contaminated cleaning materials and waste products ensures compliance with environmental standards while protecting maintenance personnel from chemical exposure hazards.

FAQ

How often should I inspect the commutator and motor shaft alignment

Inspection frequency depends on operating conditions and duty cycle. For typical industrial applications, monthly visual inspections are recommended, with detailed measurements performed quarterly. High-duty or critical applications may require weekly inspections, while low-duty motors in clean environments can often operate safely with quarterly inspections. Always increase frequency if any abnormal conditions are observed.

What are the signs that indicate commutator maintenance is needed

Key indicators include excessive sparking at the brushes, uneven wear patterns on commutator segments, visible burning or discoloration, and increased electrical noise during operation. Mechanical signs include unusual vibration, shaft runout exceeding specifications, and loose commutator segments. Any combination of these symptoms requires immediate attention to prevent further damage.

Can I perform commutator maintenance without removing the motor shaft

Basic cleaning and minor surface preparation can often be performed with the commutator in place, provided adequate access is available. However, major repairs, precise machining, or commutator replacement typically require shaft removal to ensure proper alignment and prevent damage to other motor components. Always consult manufacturer specifications for specific maintenance requirements.

What tools are essential for proper commutator maintenance

Essential tools include commutator stones for surface conditioning, undercutting tools for segment separation, precision measuring instruments for runout and alignment verification, and appropriate cleaning materials. Electrical testing equipment such as multimeters and insulation testers are crucial for performance verification. Quality tools designed specifically for commutator work provide better results and reduce the risk of component damage.