Quick-change fixtures have revolutionized the manufacturing and assembly processes of FPV motors, particularly when dealing with precise motor shaft alignment and installation. These specialized fixtures enable drone manufacturers and hobbyists to efficiently swap components during production, maintenance, and upgrades without compromising the integrity of the motor shaft assembly. The ability to rapidly reconfigure fixtures while maintaining consistent positioning accuracy has become essential for modern FPV motor production lines where precision and speed are paramount.

Modern drone manufacturing demands exceptional precision in motor assembly, where even microscopic deviations can affect flight performance and motor longevity. Quick-change fixtures address these challenges by providing repeatable positioning systems that maintain consistent alignment tolerances throughout the production cycle. The integration of these fixtures with automated production equipment has significantly reduced assembly time while improving quality control standards across the industry.

Understanding Quick-Change Fixture Technology

Mechanical Design Principles

The fundamental design of quick-change fixtures revolves around mechanical precision and repeatability. These systems typically employ spring-loaded locating pins, cam-operated clamps, and precision-ground reference surfaces to ensure accurate positioning of motor components. The motor shaft must be positioned with micron-level accuracy to prevent imbalance and ensure proper bearing alignment throughout the assembly process.

Advanced fixture designs incorporate modular components that can be rapidly reconfigured for different motor sizes and specifications. This modularity allows manufacturers to adapt their production lines for various FPV motor configurations without investing in entirely new fixture sets. The mechanical interfaces are engineered to withstand repeated cycling while maintaining their positioning accuracy over extended periods of operation.

Pneumatic and Hydraulic Actuation Systems

Many quick-change fixtures utilize pneumatic or hydraulic actuation to provide consistent clamping forces and rapid positioning movements. These systems offer precise control over clamping pressure, which is crucial when securing delicate motor shaft assemblies during manufacturing operations. The automated actuation eliminates operator variability and ensures consistent results across all production cycles.

Pneumatic systems are particularly well-suited for FPV motor assembly due to their clean operation and precise force control capabilities. The ability to program specific pressure levels ensures that motor shaft bearings and other sensitive components are secured without damage while maintaining the necessary rigidity for machining or assembly operations.

Applications in FPV Motor Manufacturing

Shaft Machining Operations

Quick-change fixtures play a critical role in motor shaft machining operations, where precise positioning is essential for achieving the tight tolerances required in high-performance FPV motors. These fixtures enable rapid setup changes between different shaft diameters and lengths while maintaining the accuracy necessary for subsequent assembly operations. The motor shaft positioning accuracy directly impacts the overall motor performance and operational lifespan.

During machining operations, the fixtures must securely hold the workpiece while allowing access to all machining surfaces. The quick-change capability enables operators to rapidly switch between different setup configurations, significantly reducing changeover time and increasing overall production efficiency. This flexibility is particularly valuable in facilities that produce multiple motor variants or handle custom motor specifications.

Assembly Line Integration

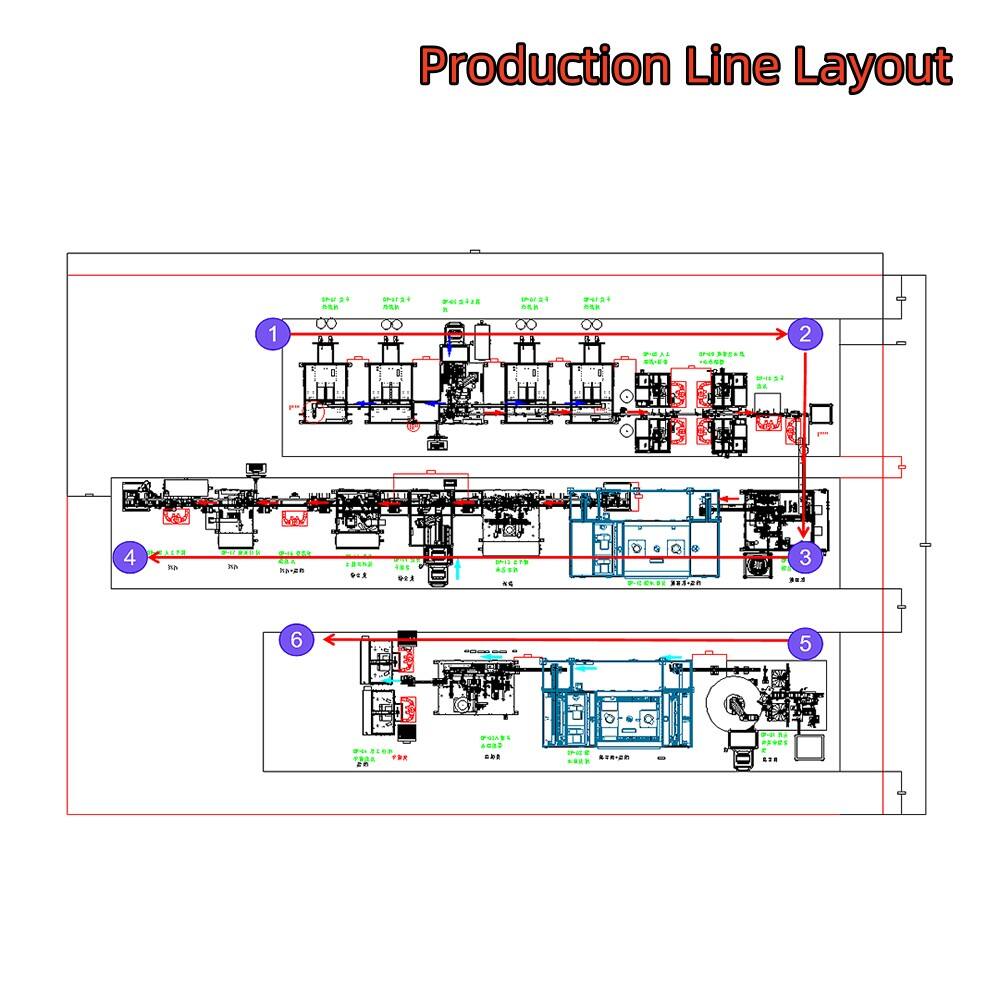

Integration of quick-change fixtures into automated assembly lines has transformed FPV motor production by enabling seamless transitions between different motor configurations. The fixtures coordinate with robotic systems to position motor shaft assemblies precisely for bearing installation, rotor mounting, and final quality verification. This integration eliminates manual handling errors and ensures consistent assembly quality.

The fixtures are designed to interface with various automation components including pick-and-place robots, torque application systems, and vision inspection equipment. This compatibility enables manufacturers to create fully automated production cells that can switch between different motor specifications with minimal operator intervention, maximizing throughput while maintaining quality standards.

Selection Criteria for Quick-Change Fixtures

Precision and Repeatability Requirements

Selecting appropriate quick-change fixtures requires careful consideration of precision and repeatability requirements specific to FPV motor manufacturing. The fixtures must maintain positioning accuracy within micrometers to ensure proper motor shaft alignment and bearing fit. This level of precision is essential for achieving the performance characteristics expected from modern FPV motors, where any imbalance can result in vibration and reduced efficiency.

Repeatability specifications become particularly important when fixtures are used across multiple production shifts or when switching between different motor variants. The fixture design must account for thermal expansion, wear patterns, and operator variation to maintain consistent performance over extended periods. Advanced fixtures incorporate temperature compensation and wear monitoring systems to maintain their accuracy throughout their operational life.

Compatibility and Flexibility Considerations

Modern FPV motor manufacturing requires fixtures that can accommodate various motor shaft diameters, lengths, and configurations without compromising positioning accuracy. The fixture design should incorporate adjustable elements that can be quickly reconfigured for different motor specifications while maintaining the necessary rigidity and precision. This flexibility enables manufacturers to respond rapidly to changing market demands and customer requirements.

Compatibility with existing production equipment and automation systems is another crucial factor in fixture selection. The fixtures must integrate seamlessly with current manufacturing processes while providing the capability to upgrade or expand production capabilities in the future. This forward compatibility ensures that the investment in quick-change fixture technology continues to provide value as production requirements evolve.

Implementation Best Practices

Setup and Calibration Procedures

Proper implementation of quick-change fixtures begins with comprehensive setup and calibration procedures that establish baseline accuracy and repeatability standards. These procedures must address motor shaft positioning accuracy, clamping force consistency, and overall system performance validation. Regular calibration schedules ensure that fixtures maintain their specified accuracy throughout their operational life.

Calibration procedures should include verification of all critical dimensions and positioning accuracy using precision measurement equipment. The motor shaft centerline position, perpendicularity to reference surfaces, and concentricity with fixture datums must all be verified and documented. This documentation provides a baseline for ongoing performance monitoring and quality assurance activities.

Maintenance and Quality Control

Establishing comprehensive maintenance protocols is essential for ensuring long-term fixture performance and reliability. These protocols should address regular inspection schedules, wear monitoring procedures, and preventive replacement of critical components. The maintenance program must account for the high-precision nature of FPV motor manufacturing and the impact that fixture degradation can have on product quality.

Quality control procedures should incorporate regular verification of fixture accuracy and performance metrics. Statistical process control techniques can be employed to monitor fixture performance trends and identify potential issues before they impact production quality. This proactive approach to quality management helps maintain consistent motor shaft positioning accuracy and overall product reliability.

Advanced Features and Technologies

Integrated Measurement Systems

Modern quick-change fixtures increasingly incorporate integrated measurement systems that provide real-time feedback on positioning accuracy and component dimensions. These systems enable immediate verification of motor shaft positioning and can detect deviations that might affect assembly quality. The integration of measurement capabilities directly into the fixture eliminates the need for separate inspection operations and reduces overall cycle time.

Advanced measurement systems can include laser interferometry, coordinate measuring capabilities, and automated go/no-go verification. These technologies provide comprehensive dimensional verification while maintaining the rapid changeover capabilities that make quick-change fixtures valuable in high-volume production environments. The measurement data can be integrated with production control systems to provide comprehensive quality documentation.

Smart Automation and Control Integration

The integration of smart automation technologies has enhanced the capabilities of quick-change fixtures by enabling predictive maintenance, automated setup optimization, and real-time performance monitoring. These systems can automatically adjust fixture parameters based on motor shaft specifications and production requirements, reducing setup time and eliminating operator errors.

Smart control systems can also provide comprehensive data logging and analysis capabilities that enable continuous improvement of fixture performance and production efficiency. The integration with enterprise manufacturing systems enables real-time production monitoring and quality tracking, providing valuable insights into fixture utilization and performance trends that can guide future equipment investments and process improvements.

FAQ

What factors determine the positioning accuracy of quick-change fixtures for motor shaft assembly

The positioning accuracy of quick-change fixtures depends on several critical factors including the precision of mechanical components, thermal stability of materials, and the design of locating and clamping systems. The fixture base and reference surfaces must be manufactured to extremely tight tolerances, typically within micrometers, to ensure consistent motor shaft positioning. Additionally, the clamping mechanism design must provide uniform force distribution without introducing distortion that could affect shaft alignment accuracy.

How do quick-change fixtures improve production efficiency in FPV motor manufacturing

Quick-change fixtures significantly improve production efficiency by reducing setup and changeover times between different motor configurations. Traditional fixtures often require extensive manual adjustment and verification procedures that can take hours to complete, while quick-change systems can accomplish the same transitions in minutes. This reduction in changeover time enables manufacturers to implement smaller batch sizes and respond more rapidly to changing production demands while maintaining consistent quality standards.

What maintenance requirements are essential for maintaining fixture accuracy over time

Maintaining fixture accuracy requires a comprehensive maintenance program that includes regular cleaning, lubrication, and calibration of all mechanical components. Critical wear points such as locating pins, clamp surfaces, and reference datums must be inspected regularly and replaced when wear exceeds acceptable limits. Additionally, the fixture should undergo periodic accuracy verification using precision measurement equipment to ensure that motor shaft positioning remains within specified tolerances throughout the fixture's operational life.

Can quick-change fixtures accommodate different motor shaft sizes and configurations

Modern quick-change fixtures are designed with modular components and adjustable elements that can accommodate a wide range of motor shaft sizes and configurations. The fixture design typically includes interchangeable bushings, adjustable clamps, and modular positioning elements that can be quickly reconfigured for different motor specifications. This flexibility enables manufacturers to use the same fixture platform for multiple product lines, reducing equipment costs while maintaining the precision necessary for high-quality motor assembly operations.

Table of Contents

- Understanding Quick-Change Fixture Technology

- Applications in FPV Motor Manufacturing

- Selection Criteria for Quick-Change Fixtures

- Implementation Best Practices

- Advanced Features and Technologies

-

FAQ

- What factors determine the positioning accuracy of quick-change fixtures for motor shaft assembly

- How do quick-change fixtures improve production efficiency in FPV motor manufacturing

- What maintenance requirements are essential for maintaining fixture accuracy over time

- Can quick-change fixtures accommodate different motor shaft sizes and configurations