Modern industrial operations demand robust aerial solutions capable of withstanding extreme environmental conditions. Industrial drone motors serve as the critical powerhouse behind these sophisticated unmanned aerial vehicles, enabling them to perfo...

VIEW MORE

High-performance motors require precision-engineered components that can withstand demanding operational conditions while delivering consistent reliability. Among the most critical elements in motor construction, custom commutator designs play a pivo...

VIEW MORE

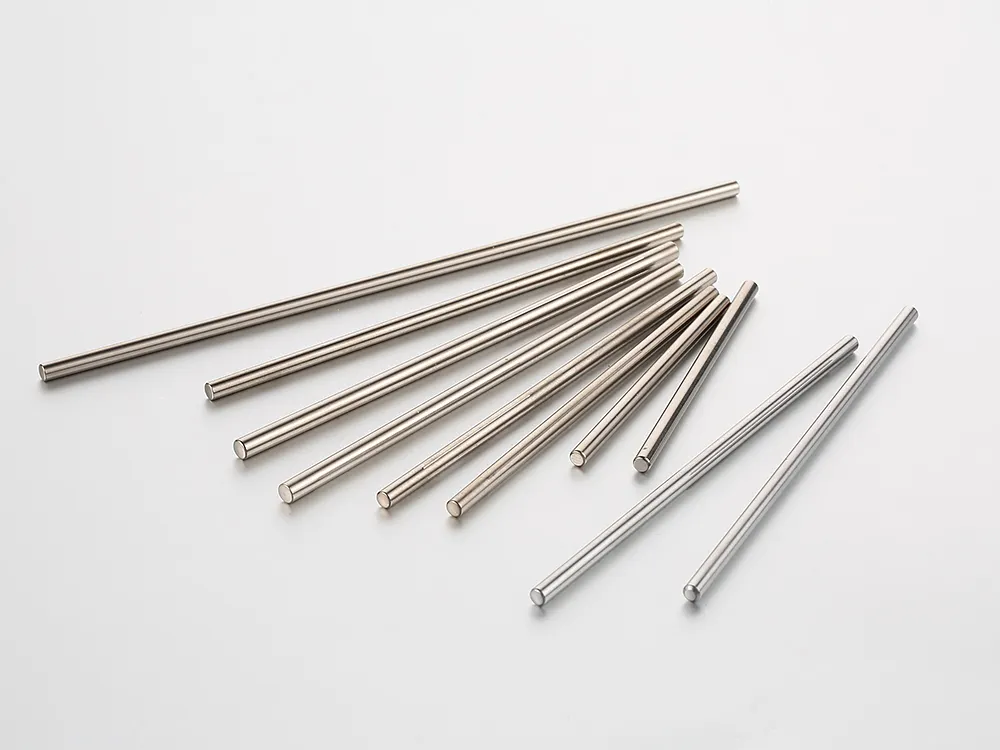

Modern manufacturing demands exceptional accuracy and reliability, particularly when dealing with rotating machinery components. Precision machining has become the cornerstone of producing high-quality shafts that meet stringent tolerance requirement...

VIEW MORE

Modern manufacturing demands have revolutionized how industrial facilities approach motor production. Motor production lines represent sophisticated engineering solutions that must adapt to diverse motor specifications, from small electric water pump...

VIEW MORE

Modern manufacturing facilities face unprecedented challenges in scaling motor production to meet growing market demands while maintaining cost efficiency and quality standards. The key to successful scalability lies in implementing strategic plannin...

VIEW MORE

Modern motor manufacturing requires precision, efficiency, and reliability to meet the growing demands of industrial applications. When motor factories scale up for mass production, selecting the right stator winding machines becomes a critical decis...

VIEW MORE

Precision manufacturing demands exceptional attention to detail, particularly when sourcing critical components like worm shafts for industrial applications. Understanding the specific machining tolerances that impact performance becomes essential wh...

VIEW MORE

Original Equipment Manufacturers (OEMs) in industrial sectors face critical decisions when specifying components for transmission systems, particularly when selecting worm shafts that will determine the operational efficiency and longevity of their m...

VIEW MORE

Electric motors power countless devices in our modern world, from power tools to industrial machinery. At the heart of many motor designs lies a critical component that ensures smooth operation and reliable performance. Understanding how this essenti...

VIEW MORE

Motor shaft maintenance and repair represent critical aspects of industrial equipment management that every engineer must master. A properly functioning motor shaft ensures optimal power transmission, reduces operational downtime, and extends the ove...

VIEW MORE

Motor shaft alignment is a critical factor in ensuring optimal performance and longevity of rotating equipment across various industrial applications. When a motor shaft operates out of alignment, it can lead to premature bearing failure, increased v...

VIEW MORE

Motor shaft problems can significantly impact the performance and longevity of industrial equipment, leading to costly downtime and repairs. Understanding how to identify and diagnose these issues early is crucial for maintaining operational efficien...

VIEW MORE