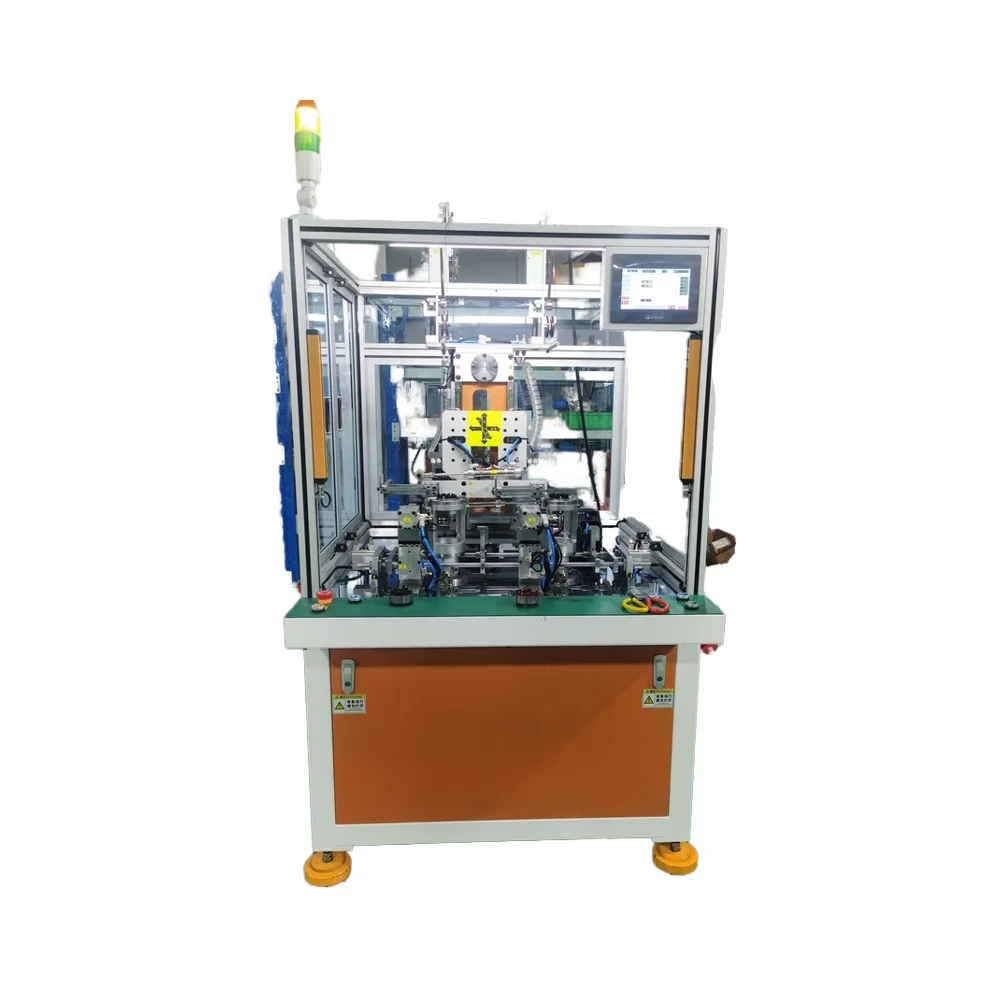

Automatic Stator Winding Machine: The Efficient and Accurate Solution for Motor Winding

In the realm of motor manufacturing, the stator winding process is a make-or-break step that directly impacts performance, reliability, and cost. For decades, manual and semi-automatic methods struggled to balance speed and precision, often leading to inconsistent windings, high scrap rates, and bottlenecks in production. Today, automatic stator winding machines have emerged as the game-changer, delivering unmatched efficiency and accuracy. These advanced systems are redefining motor winding standards, enabling manufacturers to meet the demands of industries ranging from automotive to (home appliances) with ease. Let’s explore why automatic stator winding machines are the go-to solution for modern motor winding needs.

Efficiency Redefined: Speed and Productivity

One of the most compelling advantages of automatic stator winding machines is their ability to boost production efficiency without compromising quality. Unlike manual winding, which relies on skilled operators to thread wire through stator slots—often at a rate of 10–20 small stators per hour—automatic systems operate at speeds that were once unimaginable.

A mid-range automatic stator winding machine can process 100–300 small stators per hour, with high-end models handling up to 500 units in the same timeframe. For larger stators, such as those used in industrial motors, the difference is even more striking: automatic machines can wind 10–15 units per hour, compared to just 1–2 with manual methods. This leap in productivity is driven by several key features:

- Continuous Operation: Automatic stator winding machines can run 24/7 with minimal supervision, pausing only for material reloads or scheduled maintenance. This eliminates the downtime caused by operator breaks, fatigue, or shift changes.

- Parallel Processing: Advanced models use multi-axis systems to perform multiple tasks simultaneously—loading the stator, threading the wire, winding, and unloading—reducing cycle times by 40–50%. For example, while one stator is being wound, the machine prepares the next, ensuring no idle time.

- Quick Changeovers: Switching between stator models (e.g., from a 3-slot to a 12-slot design) takes minutes with automatic machines, thanks to pre-programmed settings and modular tooling. Manual changeovers, by contrast, can take hours, disrupting production flow.

This efficiency translates to tangible cost savings. A manufacturer producing 10,000 stators monthly can reduce labor costs by 60% by replacing 10 manual stations with 2 automatic machines. Additionally, faster throughput allows businesses to fulfill larger orders, expanding their market reach.

Precision Personified: Consistency in Every Winding

Accuracy is non-negotiable in motor winding. Even minor inconsistencies—such as uneven wire tension or misaligned turns—can lead to motors that overheat, vibrate excessively, or fail prematurely. Automatic stator winding machines excel here, delivering precision that manual methods simply can’t match.

At the core of this accuracy is closed-loop control systems. These systems use sensors to monitor winding parameters (tension, speed, position) 1,000+ times per second, adjusting in real time to maintain specifications. For example, if the wire tension deviates by more than 0.1N from the target, the machine instantly adjusts the tensioner, ensuring uniform winding across all stator slots.

Other precision-enhancing features include:

- Micro-Stepping Motors: These drive the wire guide and stator rotation with increments as small as 0.01 degrees, ensuring wire is placed exactly where it needs to be—even in tight slots with diameters as small as 2mm.

- Digital Winding Programs: Operators input parameters like turns per slot, wire diameter, and winding pattern into the machine’s software, which executes the sequence with zero variation. This eliminates human error, such as miscounting turns or misjudging wire placement.

- Post-Winding Inspection: Built-in vision systems scan each stator after winding, checking for defects like crossed wires, missing turns, or insulation damage. This 100% inspection rate ensures only perfect stators move to the next production stage, reducing scrap rates from 8–10% (with manual winding) to 1–2%.

The result is motors with consistent performance. In EVs, for instance, automatic stator winding machines ensure that every motor in a production run delivers the same torque and efficiency, eliminating the “lot-to-lot” variability that plagues manual winding. This consistency is critical for meeting strict industry standards, such as ISO 9001 or IATF 16949.

Versatility: Adapting to Diverse Motor Needs

Motor designs vary widely—from tiny 12V motors in toys to 1000V+ industrial giants—and automatic stator winding machines are engineered to handle this diversity. Their versatility makes them suitable for virtually any winding application:

- Wire Types and Sizes: These machines accommodate wires ranging from ultra-thin 0.02mm enameled copper (for micro-motors in medical devices) to thick 10mm aluminum (for heavy-duty generators). They adjust tension and speed based on wire properties, preventing damage to delicate materials or slack in thicker ones.

- Winding Patterns: Whether the motor requires concentric, distributed, or hairpin windings, automatic stator winding machines can execute the design flawlessly. Hairpin winding, a complex technique where pre-formed “hairpins” are inserted into slots and welded, is particularly well-suited to automation—machines can place and weld 50+ hairpins per minute with 99.9% accuracy.

- Stator Materials: From laminations of silicon steel (common in most motors) to specialized alloys for high-temperature applications, automatic machines adapt to different materials, adjusting clamping force to avoid deformation.

This versatility is a boon for manufacturers producing multiple motor types. A single automatic stator winding machine can handle stators for both air conditioners and electric drills, reducing the need for specialized equipment and lowering capital costs.

Sustainability: Efficient Resource Use

In an era of growing environmental awareness, automatic stator winding machines offer sustainability benefits that align with green manufacturing goals:

- Reduced Material Waste: By calculating exact wire lengths and minimizing scrap (as low as 2–3% vs. 15–20% manually), these machines conserve copper and aluminum—finite resources with high production footprints.

- Energy Efficiency: While automatic machines consume more electricity than manual tools, their precision reduces the energy wasted in producing defective motors (which often end up in landfills). Additionally, the motors they help create are more efficient, consuming less energy over their lifecycle.

- Lower Emissions: Fewer defects mean fewer rework cycles, which in turn reduces the energy and emissions associated with remanufacturing. For large-scale producers, this can translate to a 10–15% reduction in carbon footprint.

FAQ: Automatic Stator Winding Machines for Efficient, Accurate Winding

What is the typical lifespan of an automatic stator winding machine?

With proper maintenance, automatic stator winding machines last 10–15 years. Critical components like servo motors and sensors may need replacement after 5–7 years, but modular designs make upgrades cost-effective.

How does the accuracy of automatic machines impact motor performance?

Precise windings ensure uniform magnetic fields in the motor, reducing energy loss by 3–5% compared to unevenly wound stators. This translates to longer battery life in EVs, lower electricity bills for appliances, and extended runtime for portable devices.

Can small manufacturers afford automatic stator winding machines?

Yes. While initial costs are higher than manual machines, smaller “entry-level” automatic models (priced around $50,000) are available, with payback periods of 2–3 years for businesses producing 5,000+ stators monthly. Many suppliers also offer financing options.

Do automatic stator winding machines require specialized training to operate?

Basic training (1–2 weeks) is sufficient for most operators. Modern machines feature user-friendly touchscreens with pre-loaded programs, and remote support from manufacturers can help troubleshoot complex issues.

How do automatic machines handle wire breakage?

Sensors detect wire breaks instantly, triggering the machine to pause, retract the broken end, and rethread the wire automatically in under 30 seconds. This minimizes downtime compared to manual rethreading, which can take 5–10 minutes per break.

Table of Contents

- Automatic Stator Winding Machine: The Efficient and Accurate Solution for Motor Winding

-

FAQ: Automatic Stator Winding Machines for Efficient, Accurate Winding

- What is the typical lifespan of an automatic stator winding machine?

- How does the accuracy of automatic machines impact motor performance?

- Can small manufacturers afford automatic stator winding machines?

- Do automatic stator winding machines require specialized training to operate?

- How do automatic machines handle wire breakage?