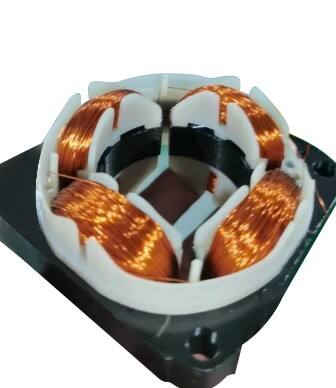

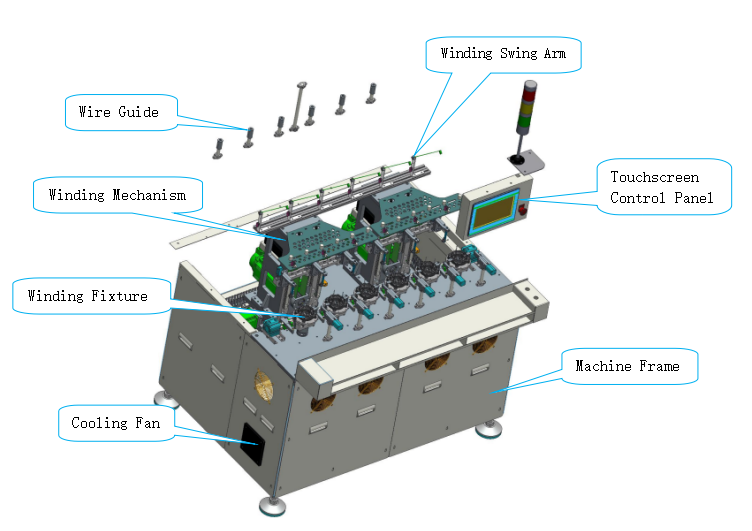

This equipment is widely suitable for stator winding of brushless inner rotor motors, primarily used in household appliances, automotive pumps, and industrial motors. Designed for products with characteristics of fine wire, thick wire, zero wire damage, low vibration, and high speed, it meets customers' demands for improved product power, quality, and efficiency. The equipment adopts Delta (Panasonic) 9-axis servo system, programmable control system, servo tension control, 10-inch touchscreen display, and integrates 1-out-of-6 automatic winding, wire cutting & clamping functions to complete the process in one go.

| Input Voltage | AC 380V ±10%, 50Hz |

| Air Supply Pressure | 0.4-0.7 MPa |

| Equipment Power | 40 kW |

| Equipment Weight | Approximately 1500 kg |

| Overall Dimensions | 1350 × 1300 × 1750 mm (L × W × H) |

| Product Range | Ф20–Ф100 mm, Stack Height: 10–50mm (Customizable) |

| Wire Diameter Range | Ф0.15–Ф0.5 mm |

| Maximum Stroke | 100 mm |

| Feeding Method | Manual |

1.The main control system adopts a motion controller, allowing technicians to freely program for different winding methods.

2.The machine operates with ten-axis servo motors and auxiliary cylinders to achieve automatic winding.

3.#1 Z-axis winding: Max speed 3500 rpm, linear guide rail, 7.5KW motor

4.#2 Z-axis winding: Max speed 3500 rpm, linear guide rail, 7.5KW motor

5.X-axis movement: Max speed 2000 rpm, ball screw, 0.75KW motor

6.Y-axis traversing: Max speed 2000 rpm, ball screw, 0.75KW motor

7.A/B/C/D axis indexing: Max speed 3500 rpm, mechanical spindle, 5.5KW motor each

8.Structure: Six-station single-needle winding machine, manual loading/unloading

9.Winding tension system: Equipped with electronic/servo motor tensioner (based on wire diameter), Φ0.1mm–Φ0.45mm

10.Automatic cutting of wire leads and ends.

11.Supports precise layer winding of single-wire stators.

12.Equipped with audible and visual alarm for low air pressure, malfunctions, and wire breaks.

13.Equipped with safety light curtains. The machine pauses when interrupted and must be manually restarted to resume, ensuring operator safety.