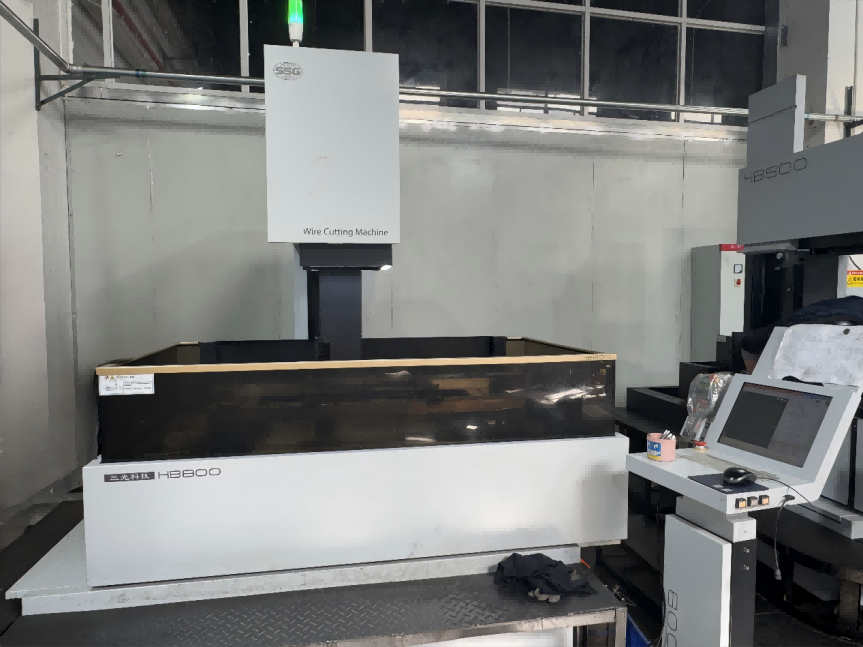

Category Specification/Description Machine Type Medium-speed Wire-cut Electrical Discharge Machine (EDM) Brand Suzhou Sanguang Technology, China Primary Application Processing of molds and mechanical components Contour Accuracy ±0...

|

Category | Specification/Description |

| Machine Type | Medium-speed Wire-cut Electrical Discharge Machine (EDM) | |

| Brand | Suzhou Sanguang Technology, China | |

| Primary Application | Processing of molds and mechanical components | |

| Contour Accuracy | ±0.005 mm | |

| Surface Roughness | Ra 0.8 μm | |

| Key Advantage | Capable of processing any conductive metals |

|

Category | Specification/Description |

| Equipment | Sumitomo Precision Injection Molding Machine (Japan) | |

| Clamping Force | 180-ton | |

| Key Feature | High injection speed | |

| Application | Optical product molding | |

| Advantage | Precision molding capabilities for high-quality optical parts |

|

Category | Specification/Description |

| Equipment Type | CNC Machining Center | |

| Key Features | - Computer Numerical Control (CNC) programming | |

| - Multi-axis machining capabilities | ||

| Applications | Aerospace components, automotive parts, precision molds, complex mechanical parts | |

| Precision | ±0.01 mm positioning accuracy | |

| Advantages | High efficiency, repeatability, and compatibility with metals/alloys (e.g., aluminum, steel) |

|

Category | Specification/Description |

| Equipment Type | Gantry Machining Center | |

| Structure | Gantry-style rigid frame design for heavy-duty machining | |

| Key Features | - Large worktable capacity | |

| - Multi-axis (3-5 axes) synchronization | ||

| Applications | Aerospace structural parts, automotive molds, shipbuilding components, energy equipment | |

| Positioning Accuracy | ±0.02 mm | |

| Advantages | High stability for oversized workpiece processing and complex surface machining |

|

Category | Specification/Description |

| Equipment Type | Precision Surface Grinding Machine | |

| Key Features | - High-precision flat surface grinding | |

| - Fine feed control system | ||

| Applications | Mold base processing, precision tooling, optical components, high-tolerance mechanical parts | |

| Grinding Accuracy | ±0.002 mm | |

| Surface Finish | Ra 0.2 μm | |

| Advantages | - Rigid structure for vibration-free operation | |

| - Suitable for hardened metals and ceramics |

|

Category | Specification/Description |

| Equipment Type | CNC Machining Center | |

| Key Features | - Computer Numerical Control (CNC) programming | |

| - Multi-axis machining capabilities | ||

| Applications | Aerospace components, automotive parts, precision molds, complex mechanical parts | |

| Precision | ±0.01 mm positioning accuracy | |

| Advantages | High efficiency, repeatability, and compatibility with metals/alloys (e.g., aluminum, steel) |

|

Category | Specification/Description |

| Equipment Type | CNC Machining Center | |

| Key Features | - Computer Numerical Control (CNC) programming | |

| - Multi-axis machining capabilities | ||

| Applications | Aerospace components, automotive parts, precision molds, complex mechanical parts | |

| Precision | ±0.01 mm positioning accuracy | |

| Advantages | High efficiency, repeatability, and compatibility with metals/alloys (e.g., aluminum, steel) |

|

Category | Specification/Description |

| Equipment Type | Georg Fischer Slow Wire EDM (Wire-cut Electrical Discharge Machine) | |

| Primary Application | Precision mold electrical discharge cutting | |

| Accuracy | ±0.003 mm | |

| Surface Finish | Ra 0.2 μm | |

| Key Advantages | - High-precision micro-cutting capability | |

| - Superior stability for complex mold profiles |

|

Category | Specification/Description |

| Equipment Type | High-Precision Mirror Surface EDM Machine (Electrical Discharge Machine) | |

| Brand | Makino (Japan) | |

| Primary Application | Precision mold manufacturing (e.g., optical lenses, medical devices, high-gloss surfaces) | |

| Accuracy | ±0.002 mm | |

| Surface Finish | Ra ≤0.1 μm (Mirror-like finish) | |

| Key Advantages | - Ultra-fine discharge control for flawless surfaces | |

| - 5-axis capability for complex 3D geometries |

|

Category | Specification/Description |

| Equipment Type | Coordinate Measuring Machine (CMM) | |

| Brand | Mitutoyo (Japan) | |

| Primary Application | Precision measurement of mechanical parts, molds, automotive/aerospace components | |

| Measurement Accuracy | ±0.5 μm | |

| Key Features | - Multi-sensor probe system | |

| - Automated scanning for complex geometries | ||

| Advantages | - High repeatability for quality control | |

| - Compatible with CAD-based metrology software |

|

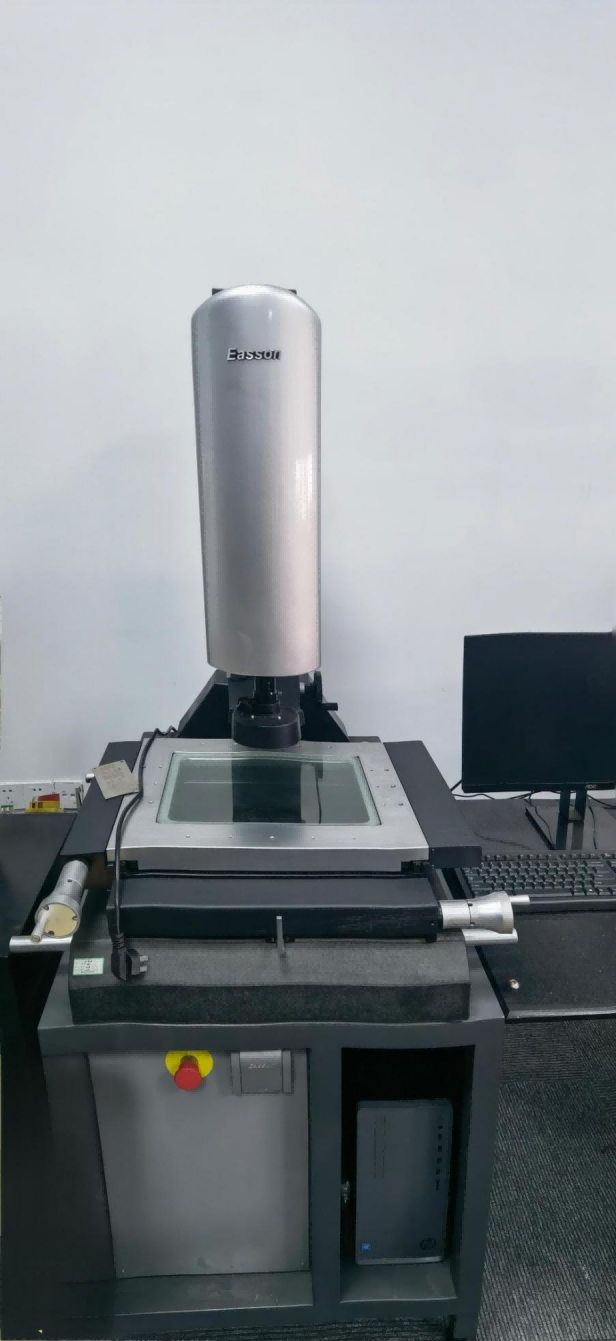

Category | Specification/Description |

| Equipment Type | Manual 2.5D Measurement System | |

| Primary Application | Measuring contour dimensions of products (e.g., mechanical parts, molds, stamped components) | |

| Key Function | - Manual operation | |

| - 2.5D contour dimension analysis | ||

| Measurement Method | Contact probe or optical sensor (depending on configuration) | |

| Accuracy | ±0.02 mm (typical) | |

| Advantages | - Cost-effective | |

| - Flexibility for small-batch inspection |

|

Category | Specification/Description |

| Equipment Type | Automatic 2.5D Measurement System | |

| Primary Application | Measuring contour dimensions of products (e.g., stamped parts, plastic molds, electronic components) | |

| Key Function | - Automated scanning and analysis of 2.5D profiles | |

| - High-speed data processing | ||

| Measurement Method | Non-contact optical sensors or motorized touch probes | |

| Accuracy | ±0.005 mm | |

| Advantages | - High efficiency for batch inspection | |

| - Integration with CAD/CAM software |

|

Category | Specification/Description |

| Equipment Type | Domestic Semi-Automatic Coordinate Measuring Machine (CMM) | |

| Primary Application | Measurement of mechanical parts, molds, and small-batch production components | |

| Operation Mode | Semi-automatic (manual positioning + automated measurement) | |

| Measurement Accuracy | ±0.01 mm | |

| Key Features | - Basic CNC programming | |

| - Touch-trigger or optical probe options | ||

| Advantages | - Cost-effective solution for domestic manufacturers | |

| - Flexible for low-to-medium precision tasks |

|

Category | Specification/Description |

| Equipment Type | Fully Automatic Image Measuring Machine | |

| Brand Origin | Japanese-imported (e.g., Keyence, Nikon, Mitutoyo) | |

| Primary Application | High-precision contour measurement of products (e.g., precision gears, electronic components, stamped parts) | |

| Key Features | - Fully automated optical scanning | |

| - Non-contact measurement via high-resolution CCD/CMOS cameras | ||

| Measurement Accuracy | ±0.002 mm | |

| Resolution | 1 μm | |

| Advantages | - High-speed batch inspection | |

| - Sub-micron repeatability for complex geometries |