Category Specification/Description Equipment Type 2D Image Measuring Machine (Video Measuring System) Primary Application Spherical Center Measurement (e.g., ball bearings, optical lenses, spherical mechanical parts) Measurement Method No...

|

Category | Specification/Description |

| Equipment Type | 2D Image Measuring Machine (Video Measuring System) | |

| Primary Application | Spherical Center Measurement (e.g., ball bearings, optical lenses, spherical mechanical parts) | |

| Measurement Method | Non-contact optical imaging with high-resolution CCD camera | |

| Key Function | - 2D coordinate calculation | |

| - Sphere center position analysis | ||

| Measurement Accuracy | ±0.001 mm | |

| Resolution | 0.5 μm | |

| Advantages | - Rapid measurement of spherical geometry | |

| - Minimal operator dependency |

|

Category | Specification/Description |

| Equipment Type | Gear Measurement Center | |

| Primary Application | Comprehensive analysis of gear parameters (e.g., spur gears, helical gears, bevel gears) | |

| Key Parameters | - Number of Teeth (Z) | |

| - Module (M) | ||

| - Pressure Angle (α) | ||

| - Helix Angle (β) | ||

| Measured Dimensions | - Tooth Width | |

| - Tip Diameter (Da) | ||

| - Root Diameter (Df) | ||

| - Base Circle Diameter | ||

| Measurement Accuracy | ±0.005 mm | |

| Advantages | - Multi-parameter synchronization | |

| - High-precision evaluation of gear geometry |

|

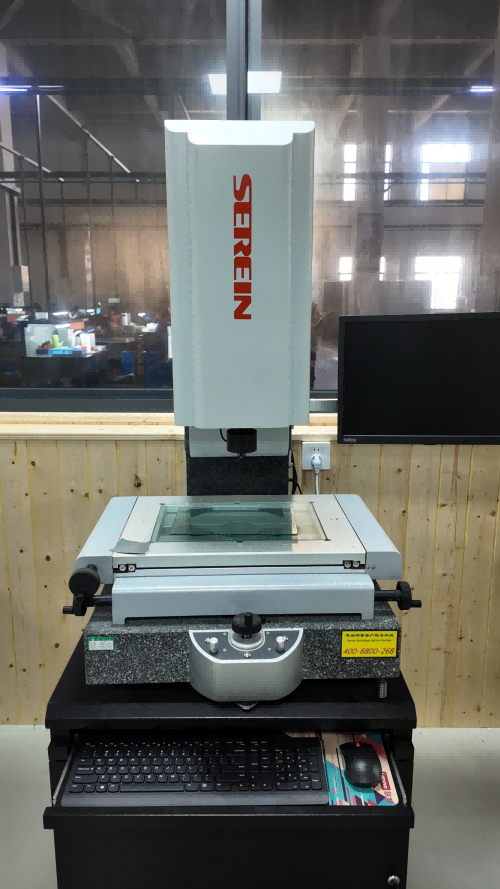

Category | Specification/Description |

| Equipment Type | Image Measuring Machine (Video Measuring System) | |

| Primary Application | Non-contact measurement of geometric parameters (e.g., precision parts, molds, electronic components) | |

| Key Functions | - Length measurement | |

| - Angle measurement | ||

| - Radius (R角) measurement | ||

| Measurement Accuracy | ±0.003 mm | |

| Resolution | 0.5 μm | |

| Measured Parameters | - Linear dimensions (length, width) | |

| - Angular features | ||

| - Fillet/Corner radii | ||

| Advantages | - High-speed optical scanning | |

| - Minimal part contact for delicate surfaces |

|

Category | Specification/Description |

| Equipment Type | Surface Roughness Tester | |

| Primary Application | Measurement of surface roughness parameters (e.g., Ra, Rz, Ry) for machined parts, molds, and precision components | |

| Key Parameters | - Ra (Arithmetic Mean Roughness) | |

| - Rz (Maximum Height of the Profile) | ||

| - Ry (Total Roughness) | ||

| Measurement Range | Ra: 0.01–20 μm | |

| Rz/Ry: 0.1–100 μm | ||

| Resolution | 0.001 μm | |

| Accuracy | ±5% (per ISO 4287 standard) | |

| Advantages | - Portable design | |

| - Contact or non-contact measurement options | ||

| - Real-time data display |

|

Category | Specification/Description |

| Equipment Type | Rockwell Hardness Tester | |

| Primary Application | Measurement of material hardness (e.g., metals, alloys, heat-treated components) | |

| Test Scale | HRC (Rockwell Hardness Scale C) | |

| Measurement Range | HRC: 20–70 | |

| Test Method | Indentation method (diamond cone indenter, total test force 150 kgf) | |

| Accuracy | ±1 HRC (per ASTM E18 standard) | |

| Advantages | - Fast and direct readout | |

| - Minimal surface preparation required | ||

| - High repeatability |

|

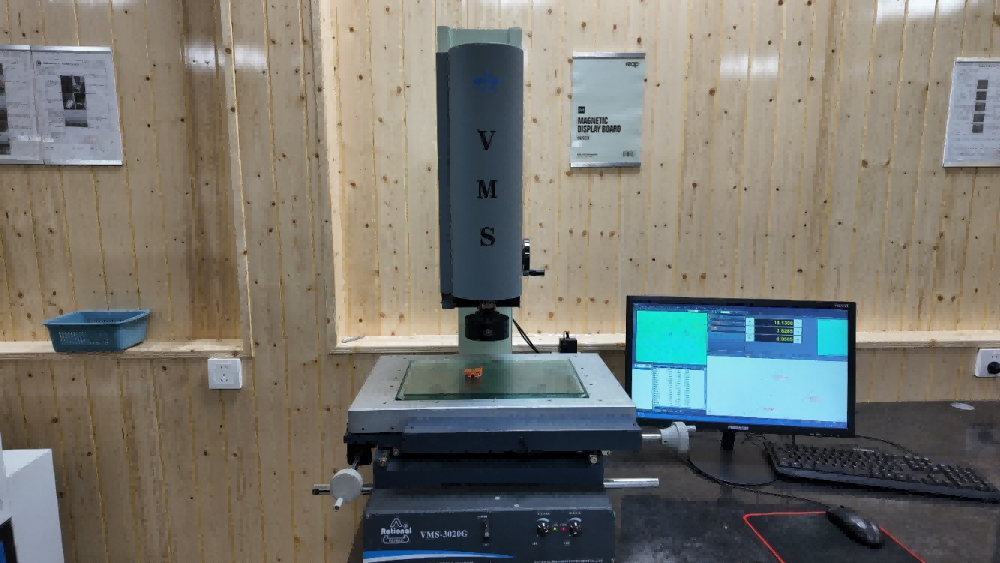

Category | Specification/Description |

| Equipment Type | Image Measuring Machine (Video Measuring System) | |

| Primary Application | Non-contact measurement of geometric parameters (e.g., precision parts, molds, electronic components) | |

| Key Functions | - Length measurement | |

| - Angle measurement | ||

| - Radius (R角) measurement | ||

| Measurement Accuracy | ±0.003 mm | |

| Resolution | 0.5 μm | |

| Measured Parameters | - Linear dimensions (length, width) | |

| - Angular features | ||

| - Fillet/Corner radii | ||

| Advantages | - High-speed optical scanning | |

| - Minimal part contact for delicate surfaces |

|

Category | Specification/Description |

| Equipment Type | Roundness Measuring Instrument | |

| Primary Application | Detection of shaft roundness and harmonic analysis (e.g., rotating components, bearings, precision shafts) | |

| Key Parameters | - Roundness Error | |

| - Harmonic Components (e.g., vibration analysis) | ||

| Measurement Accuracy | ±0.1 μm | |

| Resolution | 0.01 μm | |

| Measurement Method | Rotating sensor or precision spindle with contact/non-contact probes | |

| Advantages | - High-precision evaluation of circular profiles | |

| - Dynamic harmonic distortion analysis |