Category Specification/Description Equipment Type Roundness Tester Primary Application Measurement of circularity (roundness error) for rotating components (e.g., commutators,shafts, bearings, precision gears) Key Parameters - Roundness d...

|

Category | Specification/Description |

| Equipment Type | Roundness Tester | |

| Primary Application | Measurement of circularity (roundness error) for rotating components (e.g., commutators,shafts, bearings, precision gears) | |

| Key Parameters | - Roundness deviation | |

| - Harmonic components (e.g., 2nd to 50th harmonics) | ||

| - Cylindricity (optional) | ||

| Measurement Accuracy | ±0.1 μm | |

| Resolution | 0.01 μm | |

| Measurement Method | Contact probe (diamond stylus) or non-contact laser scanning | |

| Advantages | - High-precision analysis of rotational symmetry | |

| - Dynamic harmonic distortion diagnosis |

|

Category | Specification/Description |

| Equipment Type | Overspeed Test Bench | |

| Primary Application | Performance and safety testing of rotating machinery under overspeed conditions (e.g., turbines, engines, high-speed rotors) | |

| Key Parameters | - Maximum test speed: 1.5× rated speed (customizable) | |

| - Speed control accuracy: ±0.5% | ||

| Measurement Metrics | - Vibration analysis | |

| - Temperature rise | ||

| - Structural deformation monitoring | ||

| Safety Features | - Emergency braking system | |

| - Real-time anomaly detection and shutdown | ||

| Advantages | - Simulates extreme operating conditions | |

| - High-precision dynamic data acquisition |

|

Category | Specification/Description |

| Equipment Type | High-Temperature Tester | |

| Primary Application | Performance evaluation of materials, electronic components, or mechanical systems under elevated temperatures (e.g., aerospace, automotive, energy sectors) | |

| Temperature Range | Ambient to 1500°C (customizable) | |

| Control Accuracy | ±1°C | |

| Key Functions | - Thermal cycling | |

| - High-temperature durability testing | ||

| - Heat resistance analysis | ||

| Measurement Metrics | - Temperature stability | |

| - Material expansion/contraction | ||

| - Electrical/mechanical property degradation | ||

| Advantages | - Precise temperature simulation | |

| - Real-time data logging | ||

| - Safety interlocks for overheating protection |

|

Category | Specification/Description |

| Equipment Type | Pressure Tester | |

| Primary Application | Pressure testing of components (e.g., pipelines, valves, hydraulic systems, pressure vessels) | |

| Pressure Range | 0–100 MPa (customizable) | |

| Accuracy | ±0.5% FS (Full Scale) | |

| Key Functions | - Leak detection | |

| - Burst pressure testing | ||

| - Pressure cycle endurance evaluation | ||

| Safety Features | - Overpressure relief valve | |

| - Emergency shutdown | ||

| - Real-time pressure monitoring | ||

| Advantages | - High-stability pressure control | |

| - Compatibility with liquids/gases | ||

| - Data traceability |

|

Category | Specification/Description |

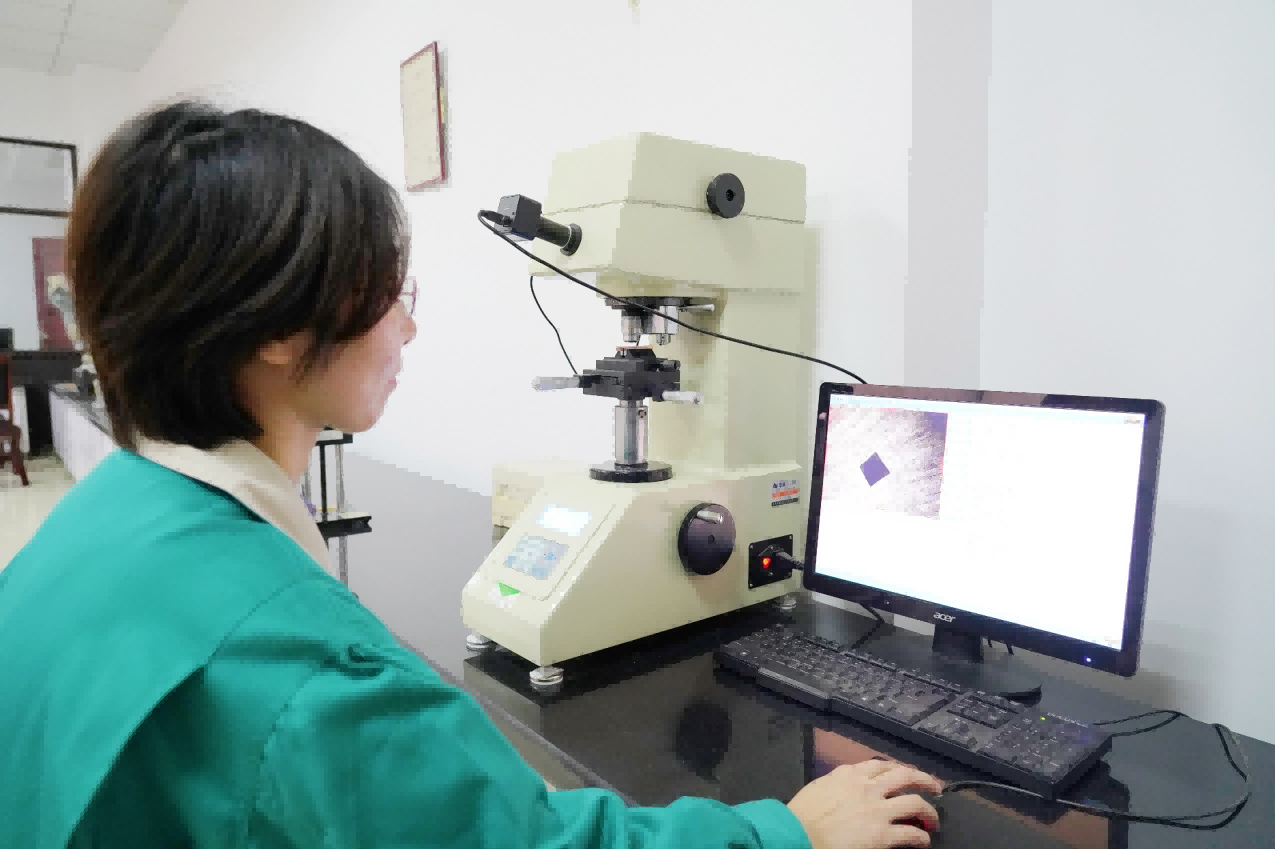

| Equipment Type | Hardness Tester | |

| Primary Application | Measurement of material hardness (e.g., metals, alloys, plastics, heat-treated components) | |

| Test Methods | - Rockwell (HRC, HRB) | |

| - Vickers (HV) | ||

| - Brinell (HB) | ||

| - Shore (for polymers) | ||

| Measurement Range | - Rockwell: 20–100 HRC | |

| - Vickers: 1–3000 HV | ||

| - Brinell: 8–650 HB | ||

| Accuracy | ±1% (per ASTM E18, ISO 6508 standards) | |

| Key Features | - Automatic load application | |

| - Digital display with hardness conversion charts | ||

| Advantages | - Versatile for multiple materials | |

| - Portable or benchtop configurations available |